If Spacecrafts of Tomorrow Were Made With Bones

2014.02.13

Scientists in Germany are using a 3D printer to replicate a synthetic material that replicates the super strong structure of bone. It could mean a breakthrough for how we build everything. Including a spacecraft in the future.

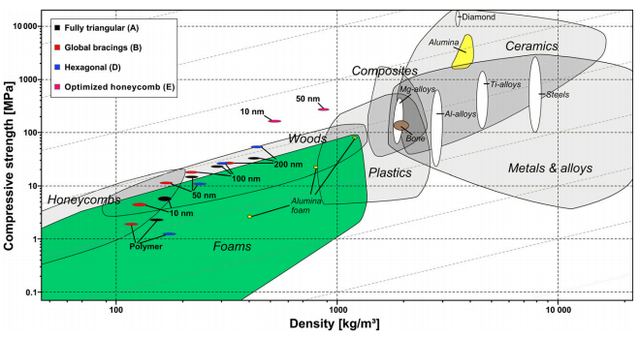

According to the study published in the Proceedings of the National Academy of Sciences, it takes a look a ta fundamental problem with material sciences - the trade-off between weight and strength. Heavier materials tend to be stronger, like steel, while lighter materials are less stable.

Bones are an exception to this rule though. they form structures made of collagen and hydroxyapatite at a microscopic scale, and like tiny columns and floor plates filled with air, they are light and strong.

Jens Bauer explains the concept:

Technical foams are very light, but compared with bulk materials, their strength is quite low because of their random structure. Natural lightweight materials, such as bone, are cellular solids with optimized architecture. They are structured hierarchically and actually consist of nanometer-size building blocks, providing a benefit from mechanical size effects

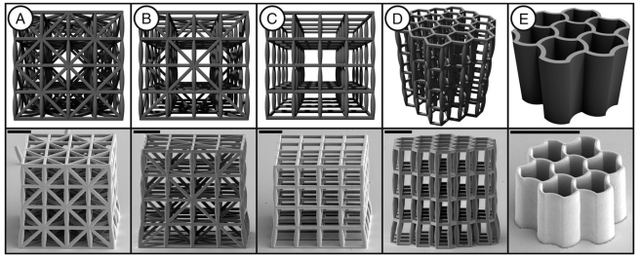

Using 3D laser lithography, Bauer's team printed nano-scale structures using ceramic–polymer—the same basic stuff of our own bones. They were able to test the compressive strength of synthetic bone at the same scale as the real stuff.

It would be really interesting to see whether a spacecraft can be made using bones. What do you think?

[The Proceedings of the National Academy of Sciences; LATimes]

More Articles

Copyright © Fooyoh.com All rights reserved.