Your iPhone Probably Costs $12.50 to $30 to Make

2016.03.05

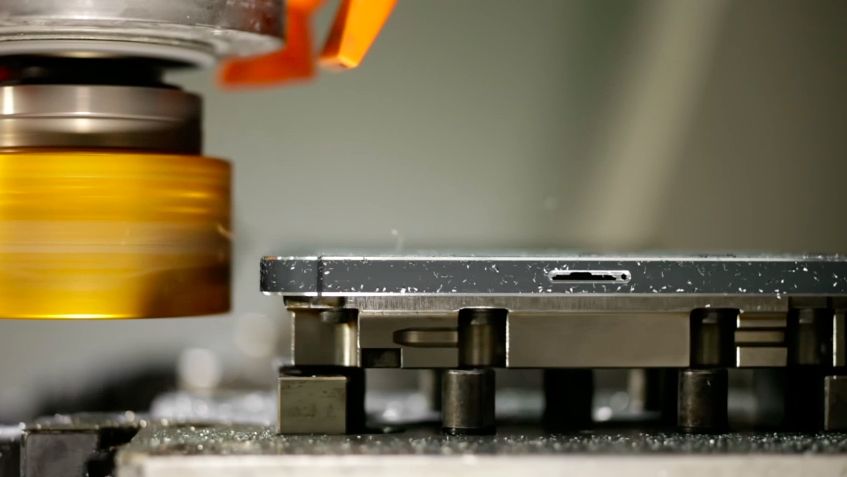

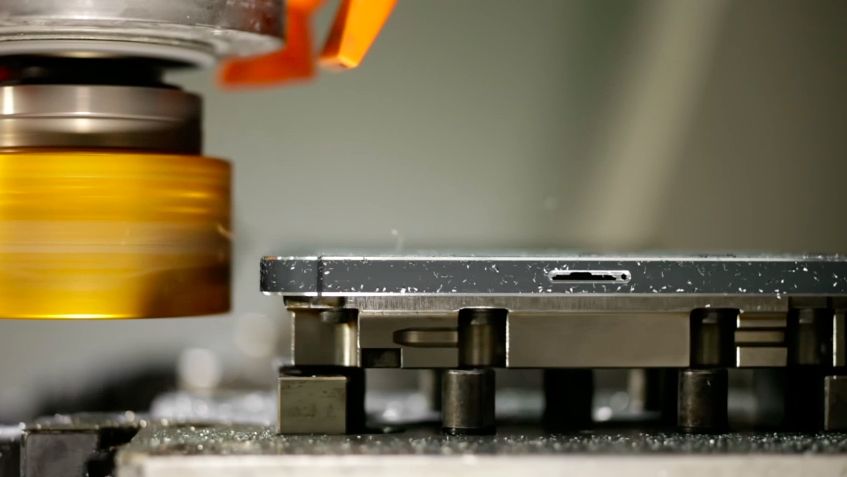

A rare peek into Apple's factory in China gives us a clue as to how much your iPhone probably costs to make. It's so cheap. And no wonder, the company is super rich. Either way, they're pretty good at making the phones look expensive.

Reporter Bill Weir got to see some things no one else sees. He wrote in his article:

Though Apple products are labeled “designed in California” by the Cupertino based company, the products “would be nothing without the relentless, repetitive work of hundreds of thousands of Chinese and Taiwanese workers like Liang Juan,” writes Weir. He noted that a majority of the laborers in the factory were in their late teens to twenties.“17 hours of labor input would imply $30 labor cost per iPhone. That seems a lot higher than the industry.”

Of course, his quote does not account for costs like material, shipping or marketing. He gave more exact calculations as the ABC report mentioned that there were presumably 141 labor work steps in the production of an iPhone.“For example, if each step in the human assembly process took 2 minutes then human hands will touch the iPhone for 423 minutes or about 7 hours. This would imply a labor cost for an iPhone of about $12.50.”

He did say, though that:

“Manufacturing costs for the iPhone are likely to be much higher than comparable devices. This is partly because of the design of the product and partly because of the quality testing needed.More Articles

Copyright © Fooyoh.com All rights reserved.