The Role of Storage Containers in Global Supply Chain Management

2024.02.18

In today’s fast-paced global economy, the efficiency of supply chains is paramount. One often overlooked hero in the realm of logistics and supply chain management is the humble storage container. These steel boxes, which come in various shapes and sizes, play a pivotal role in ensuring goods are transported safely and efficiently across the globe. This article delves into the multifaceted role of storage containers in global supply chain management, showcasing their significance from historical evolution to future trends.

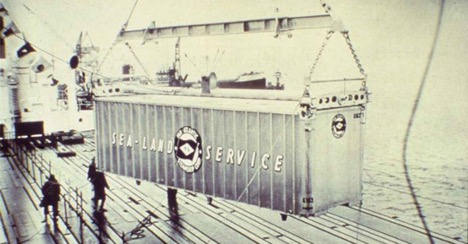

The Evolution of Storage Containers

The concept of containerization isn't new. The modern shipping container was invented in the 1950s by Malcolm McLean, revolutionizing international trade and leading to the globalization of supply chains. Before containers, goods were manually loaded onto ships, a labor-intensive and time-consuming process known as break-bulk shipping. Containers enabled standardized handling, making loading and unloading dramatically more efficient.

The introduction of containerization brought about a paradigm shift in the logistics industry. It simplified the process of transporting goods, reducing labor costs, and significantly decreasing the time required for loading and unloading cargo. This newfound efficiency paved the way for the expansion of global trade, as goods could be transported more reliably and at a lower cost.

Types of Storage Containers

Storage containers come in various forms to cater to different cargo needs. The most common type is the standard dry storage container, which is used for a wide range of goods, including electronics, clothing, and machinery. These containers are designed to be weather-resistant, protecting the cargo from external elements during transit.

For perishable goods, refrigerated containers, commonly known as reefers, maintain specific temperature conditions to preserve the freshness and quality of the cargo. This type of container is crucial for transporting food products, pharmaceuticals, and other temperature-sensitive items.

Open-top containers and flat-rack containers are ideal for oversized cargo that cannot be loaded through the traditional doors of standard containers. Open-top containers have a removable top, allowing for easy loading and unloading of tall items such as machinery or vehicles. Flat-rack containers have collapsible sides, making them suitable for carrying heavy and bulky cargo, including construction equipment and large pipes.

In addition to these types, there are also tank containers specifically designed for transporting liquids, such as chemicals or food-grade liquids. These containers have specialized fittings and coatings to prevent leakage and ensure the safe transportation of liquids.

Advantages of Using Storage Containers in Supply Chains

Standardization and Intermodal Transportation

The standardization of container sizes (typically 20 or 40 feet) has streamlined intermodal transportation, allowing containers to be easily transferred between ships, trains, and trucks. This seamless transition reduces handling costs and minimizes the risk of damage. Containers can be loaded onto a ship, transported to a port, seamlessly transferred onto a train or truck, and delivered to the final destination without the need to unload and reload the cargo.

This standardized approach has revolutionized the logistics industry, enabling goods to be transported across multiple modes of transportation without the need for manual handling or repackaging. It has also facilitated the growth of intercontinental trade, as containers can be efficiently loaded onto large container ships and transported across oceans.

Security and Durability

Constructed from high-quality steel, containers like those offered by Storage-Tech are designed to withstand harsh conditions, protecting the cargo within. They are built to be weather-resistant, ensuring that goods remain safe and secure during transportation.

The robust construction of storage containers provides an added layer of security for valuable goods. With their sturdy doors and locking mechanisms, containers deter theft and unauthorized access. This level of security is especially crucial for high-value items or sensitive cargo.

In addition to security, the durability of storage containers ensures that goods can be securely stored and transported across long distances without concern. They are designed to withstand extreme weather conditions, including heavy rain, strong winds, and even saltwater exposure during maritime transport. This durability minimizes the risk of damage to the cargo, providing peace of mind to shippers and consignees.

Efficiency and Cost-effectiveness

The use of storage containers optimizes space usage, both in transit and storage facilities, reducing shipping and storage costs. Containers are designed to be stackable, allowing for efficient utilization of space on ships, trains, and trucks. This maximization of space translates into cost savings, as more goods can be transported in a single trip.

Furthermore, the standardized size of storage containers simplifies the loading and unloading process. Forklifts and cranes can easily handle containers, minimizing the time and effort required for cargo handling. This efficiency not only reduces labor costs but also ensures quicker turnaround times, enabling businesses to meet customer demands more effectively.

Storage Containers and Global Trade

Storage containers are the backbone of international trade, facilitating the efficient import and export of goods. By simplifying logistics operations, they contribute significantly to global economic growth.

The use of storage containers has enabled businesses to expand their markets beyond national borders. Companies can now source raw materials and finished products from different parts of the world, opening up new opportunities for growth and innovation. The ability to transport goods in large quantities and at a lower cost has made global trade more accessible to businesses of all sizes.

Moreover, storage containers have played a vital role in the development of free trade zones and special economic zones. These designated areas offer incentives and streamlined processes for businesses engaged in international trade. Storage containers provide the necessary infrastructure to support the operations of these zones, allowing for efficient movement of goods and attracting foreign investments.

Technological Innovations in Container Usage

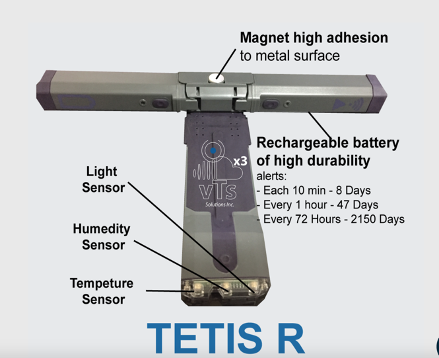

Image Courtesy Of Tetis

The integration of technology has further enhanced the role of storage containers in supply chain management. Smart containers, equipped with IoT devices, have transformed traditional containers into connected assets. These devices can monitor various parameters such as location, temperature, humidity, and even vibrations during transit.

Real-time tracking and condition monitoring provided by smart containers enable businesses to have better visibility and control over their supply chains. They can track the movement of goods, identify potential bottlenecks, and proactively address any issues that may arise. This level of transparency improves supply chain efficiency and helps in mitigating risks associated with delays or damage to the cargo.

Automation is another technological advancement that has revolutionized container management. Automated ports and container management systems use robotics and artificial intelligence to streamline the handling and tracking of containers. These systems can efficiently load and unload containers from ships, sort them for onward transportation, and provide real-time updates on container movements.

The integration of technology in container usage has not only improved operational efficiency but also enhanced security and safety. With advanced tracking systems and automated processes, the risk of theft, damage, or loss of containers is significantly reduced.

Challenges in Container Management

Despite their advantages, managing storage containers presents challenges to the logistics industry. One of the primary challenges is container shortages and imbalances. The demand for containers fluctuates based on various factors, including global trade patterns, economic conditions, and geopolitical events. When there is a shortage of containers in certain regions or ports, it can lead to delays and increased costs for shippers.

Efforts are being made to address this challenge by increasing container production and optimizing container flows. Container manufacturers are continuously investing in expanding their production capacities to meet the growing demand. Additionally, shipping lines and logistics providers are working towards better container repositioning strategies to ensure a more balanced supply of containers worldwide.

Another challenge in container management is the environmental impact associated with their production and disposal. Containers are typically made from steel, which requires significant energy and resources for manufacturing. The industry is exploring sustainable alternatives, such as using eco-friendly materials and implementing recycling programs to minimize the environmental footprint of storage containers.

Storage Containers in Crisis Management

Storage containers have proven to be invaluable in crisis management situations. During natural disasters or humanitarian emergencies, storage containers have been repurposed for disaster relief housing, medical clinics, and temporary storage facilities. Their versatility and mobility make them ideal for quickly establishing infrastructure in affected areas.

In disaster-stricken regions, storage containers can be converted into temporary shelters, providing a safe and secure environment for displaced individuals. These containers can be easily transported to the affected areas and set up quickly, offering immediate relief to those in need.

Furthermore, storage containers serve as temporary storage facilities for relief supplies, medical equipment, and food provisions. They provide a secure and weather-resistant space to store critical resources until they can be distributed to the affected communities.

The Future of Storage Containers in Supply Chains

The future of storage containers in supply chains looks promising, with ongoing advancements in technology and sustainability practices. As global trade continues to evolve, the role of storage containers will undoubtedly expand, further solidifying their importance in efficient supply chain management.

Technological innovations, such as the Internet of Things (IoT) and artificial intelligence, will continue to enhance container tracking, security, and efficiency. Smart containers will become more prevalent, enabling real-time visibility of cargo and facilitating proactive decision-making in supply chain operations.

Sustainability will also play a significant role in the future of storage containers. The industry is exploring eco-friendly materials and manufacturing processes to reduce the environmental impact of container production. Recycling initiatives and circular economy principles will gain more prominence, ensuring that end-of-life containers are repurposed or recycled responsibly.

As supply chains become more complex and global trade continues to expand, the versatility and efficiency of storage containers will remain indispensable. They will continue to be an integral part of the logistics industry, enabling businesses to transport goods reliably, securely, and cost-effectively.

Conclusion

From their inception to the modern day, storage containers have played a crucial role in the development and efficiency of global supply chains. Their versatility, durability, and cost-effectiveness make them indispensable in the logistics industry. As we look towards the future, it's clear that storage containers will continue to be at the heart of global trade, driving innovation and efficiency in supply chain management.

Storage containers will continue to revolutionize the way goods are stored, transported, and distributed worldwide. Their standardized design, security features, and cost-effectiveness make them an essential component of global supply chain management. Businesses that embrace the versatility and efficiency of storage containers will gain a competitive edge in an increasingly interconnected and dynamic global marketplace.

More Articles

Copyright © Fooyoh.com All rights reserved.